Reuse, resale, and recycling

Reuse is among our top priorities. Returned devices that can be reused are remanufactured, refurbished, or repaired, and resold by Cisco Refresh, or used by Cisco service operations or our internal labs. Products that are not reusable are harvested for components and recycled by one of our authorized recyclers. With the Send IT Back app, customers simply take photos of the products they want to return, and shipping agents contact them to arrange a free pickup. As of fiscal 2023, the Send IT Back app is available in in 27 European Union countries, the United Kingdom and the United States. The ease with which a customer or partner can now process returns directly contributed to a doubling of customers and partners using the tool between fiscal 2021 and fiscal 2022. CRS, our customer and partner recycling solution, remains available for those with nonworking product for equipment to be recycled in a secure and responsible manner. Cisco is developing a long-term roadmap to expand the ease and simplicity of product returns.

Alongside our efforts to increase the reuse of equipment, we work to address external barriers to scale these opportunities. We collaborate with peer companies, nongovernmental organizations (NGOs), and policymakers to address challenges and unintended consequences that can impact our ability to repair equipment.

Reuse and resale programs

When products are returned to Cisco, we evaluate their condition and eligibility for reuse. If the product is in usable condition or repairable and there is demand for the product, it undergoes a testing and/or repair process to meet Cisco’s quality standards. Cisco prioritizes data security by performing data sanitization to NIST 800-88 R1 specifications prior to reuse.

- R2A—Our Return to A-Stock program sends unused products from our distribution centers to be reused by our contracted manufacturing sites. Returned products that are considered “new-in-box” are sent back to be tested and, if necessary, reconfigured. This allows us to better reuse products while also improving our ability to satisfy demand for new equipment without new manufacturing.

- Services—CX evaluates products returned under service contracts for reparability. Repairable items are delivered to service repair vendors that categorize, repair, and refurbish products. Once repair is complete, these items are shipped to Service Logistics warehouses to be supplied as advanced replacement parts to other customers and partners in the event of a Service RMA. CX keeps replacement parts strategically located near its customers to maximize RMA response efficiency and minimize transport emissions.

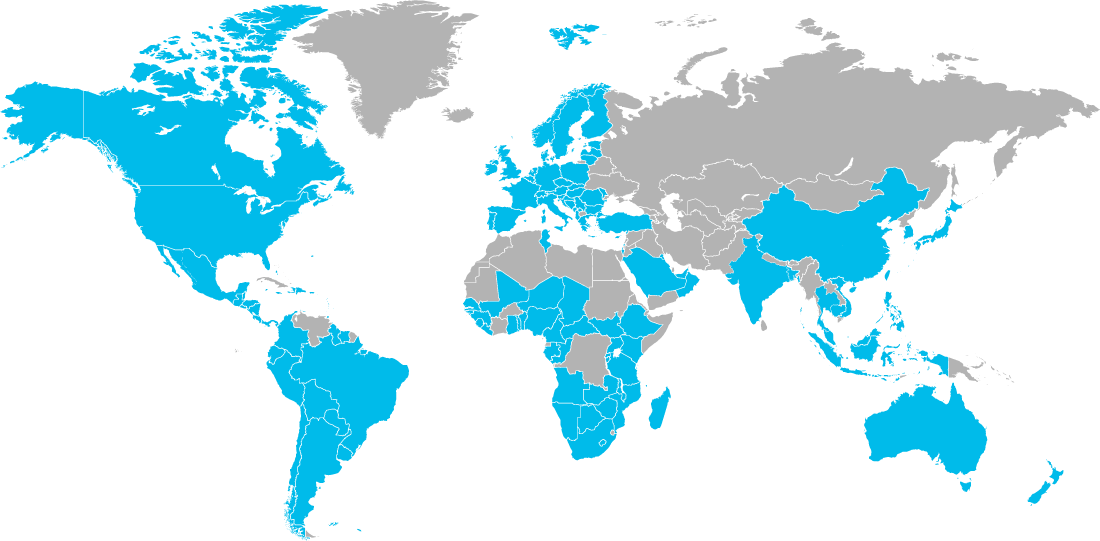

- Cisco Refresh—Cisco’s certified remanufactured products are backed by the same Cisco warranty and service options as new products. Equipment is sold through Cisco authorized resellers and is available in more than 70 countries. Inventory includes products from technology areas including switching, routing, wireless, IP telephony, security, and other advanced technologies.

- Repo Depot—The Repo Depot program collects and redistributes lab equipment for Cisco internal use in the United States. In fiscal 2023, Repo Depot redistributed nearly 9824 items, representing an estimated cost avoidance of over US$6.4 million while diverting approximately 60,000 pounds of equipment from Cisco’s recycling stream.

Recycling programs

Cisco's ambition is to redeploy as much material as possible, which includes recycling and harvesting of commodity components. We currently have two contracted e-scrap recyclers. Each recycler uses both company-owned facilities and subcontracted recyclers to provide global recycling coverage. Cisco’s contracted recyclers are certified to one or more e-scrap-specific recycling standards, such as R2, R2 RIOS, eStewards, and WEEELABEX.

In addition, our contracts require recyclers to enforce our recycling processes with their subcontractors doing Cisco work. We approve prospective recycling companies and recycling locations before sending Cisco equipment for processing.

Contracted recyclers provide Cisco with monthly reports showing cases opened and processed on a lot-by-lot basis. Reports include a mass balance showing the weight as received and the weights of each fractional commodity adding up to the gross weight received. On a quarterly basis, we hold business reviews with the recyclers to review recent results, action items, and upcoming focus areas. We also conduct random site audits of recycling facilities.

After material is received and weighed on a calibrated scale, recyclers review items for possible component harvesting. They may harvest processors, memory, and other hardware with sufficient market value to offset the cost of their harvesting, cleaning, packaging, and resale. Harvested components must be cleared of data in compliance with the NIST 800-88 R1 standard before being available for resale.

After harvesting, the unit proceeds to the recycling process. The recycling process starts with each load of e-scrap being dismantled and sorted into “commodity fractions.” This separates steel, aluminum, cardboard, plastic, wire/cable, and printed circuit boards (PCBs). PCBs are shredded and sorted further before going to a specialized smelter where copper, palladium, silver, and gold are recovered. These metals are then sold on the global metals markets.

Other materials, including batteries or packaging materials, are sent to downstream recyclers to become raw material inputs for new products.

Read about Cisco’s Environmental Management System (EMS) and compliance with relevant environmental regulations, such as Waste Electrical and Electronic Equipment (WEEE), Battery & Packaging Compliance, under Environmental Compliance.